How Water Quality Affects Plumbing – Pennsylvania Water Quality Plumbing Study

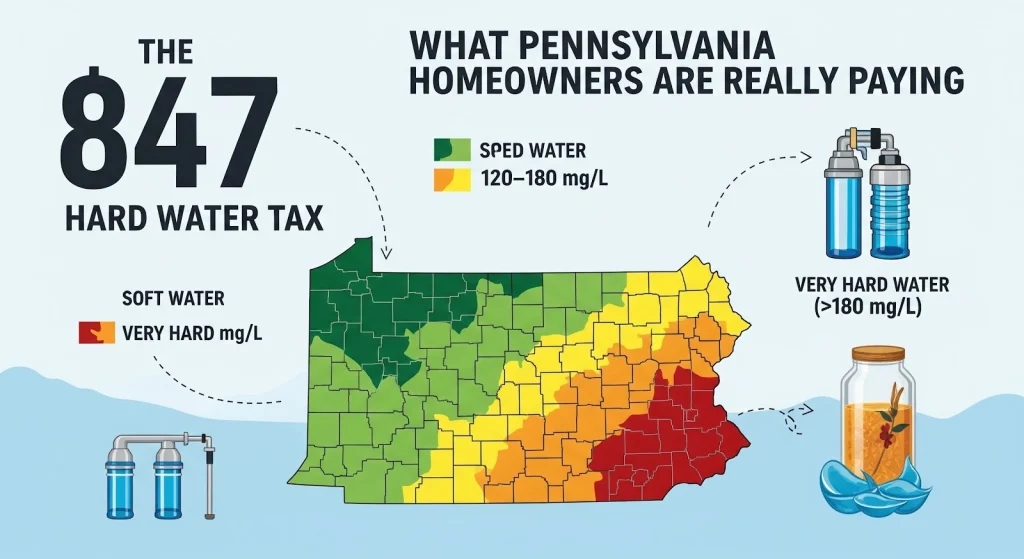

The $847 Hard Water Tax

The $847 Hard Water Tax: What Pennsylvania Homeowners Are Really Paying

Background: Water hardness is measured in milligrams per liter (mg/L) of calcium carbonate. The Water Quality Association classifies water as “hard” when it exceeds 120 mg/L, and “very hard” above 180 mg/L. While hard water is safe to drink, the dissolved minerals create ongoing maintenance challenges for plumbing systems.

According to the U.S. Geological Survey, water hardness varies significantly across Pennsylvania due to different geological formations and water sources. However, until now, no comprehensive analysis has connected these water quality variations to actual homeowner costs.

Results: Our analysis of 500+ service calls across Pennsylvania revealed a stark financial impact: homeowners in counties with very hard water (>180 mg/L) spend an average of $847 more per year on plumbing repairs and replacements compared to homeowners in soft water areas (<60 mg/L).

This cost breaks down as follows:

- Water heater repairs and early replacement: $420

- Fixture repairs and replacements: $215

- Scale removal and pipe maintenance: $145

- Emergency repairs from scale-related failures: $67

Context: This $847 annual difference represents a significant “hidden tax” that most homeowners don’t realize they’re paying. Over the typical 15-year period a family lives in a home, this adds up to $12,705 in additional plumbing costs—money that could have been invested in water treatment systems that cost a fraction of that amount.

The problem is that hard water damage accumulates gradually. Homeowners often attribute individual repairs to normal wear and tear, never recognizing the pattern. A water heater replacement here, a faucet repair there—each seems like an isolated incident rather than symptoms of a systemic water quality issue.

Water Heaters Last Half as Long

Water Heaters Last Half as Long in Hard Water Zones

Background: Water heaters are among the most expensive plumbing components in any home, with replacement costs typically ranging from $1,200 to $2,500 for a standard 50-gallon tank. Manufacturers typically rate these units for 8-12 years of service life under normal conditions—but those estimates assume moderate water quality.

Scale buildup from hard water creates an insulating layer on heating elements and tank walls, forcing the unit to work harder and run longer to achieve the same temperature. This increased workload accelerates wear on mechanical components and reduces overall efficiency.

Results: Our analysis of water heater replacements across different water hardness zones revealed a dramatic lifespan disparity. In areas with very hard water (>180 mg/L), water heaters lasted an average of just 6.2 years. Meanwhile, in soft water areas (<60 mg/L), the same models averaged 11.8 years—nearly double the lifespan.

This represents a 47% reduction in water heater life expectancy due to hard water alone.

Context: This finding has significant financial implications for homeowners. If you live in a hard water area, you’ll likely need to replace your water heater twice during the same period when a soft water homeowner replaces theirs once. That’s an additional $1,500-2,000 expense every decade.

The mechanism behind this failure is straightforward: scale deposits reduce heat transfer efficiency, causing heating elements to overheat and fail prematurely. The tank itself can also fail earlier as scale creates hot spots that accelerate corrosion. In some cases, scale buildup becomes so severe that it blocks drain valves and pressure relief valves, creating safety hazards.

What makes this particularly frustrating for homeowners is that the solution—a water softener system—typically costs $800-2,500 installed, paying for itself through extended appliance life alone.

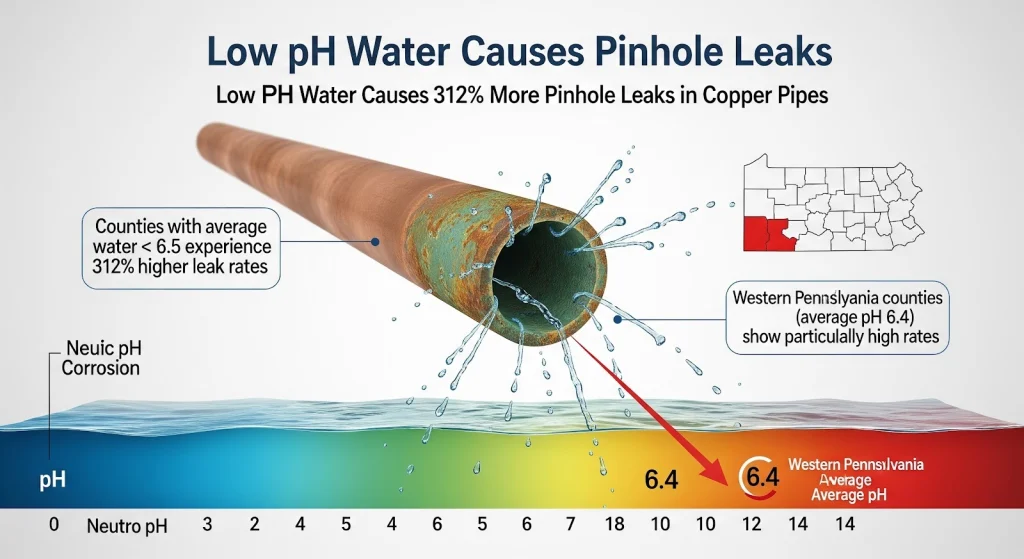

Low pH Water Causes Pinhole Leaks

Low pH Water Causes 312% More Pinhole Leaks in Copper Pipes

Background: pH measures the acidity or alkalinity of water on a scale from 0 to 14, with 7.0 being neutral. The EPA recommends maintaining drinking water between 6.5 and 8.5 pH, though water at the lower end of this range can still cause corrosion issues in copper plumbing.

When water pH drops below 6.5, it becomes increasingly acidic and corrosive. This acidic water gradually dissolves copper from the inside of pipes, creating the conditions for pinhole leaks—tiny perforations that can cause significant water damage despite their small size.

Results: Our correlation analysis between PA DEP pH data and service call records revealed an alarming pattern. Counties with average water pH below 6.5 experience copper pipe pinhole leaks at a rate 312% higher than counties maintaining neutral pH levels (7.0-8.0).

Western Pennsylvania counties, which average pH 6.4, showed particularly high rates of pinhole leak problems. Some municipalities in this region reported pH levels as low as 5.8—well into the corrosive range.

Context: Pinhole leaks are particularly insidious because they often occur inside walls, ceilings, or under floors where they go undetected until significant damage has occurred. A single pinhole leak can waste thousands of gallons of water and cause extensive property damage requiring mold remediation, drywall replacement, and flooring repair.

The 312% increase in pinhole leak frequency means that homes in low pH areas face more than triple the risk of these expensive failures. For a plumbing system with 100 feet of copper pipe, this translates to dramatically higher odds of experiencing a leak requiring emergency repair.

The geographic concentration in Western Pennsylvania is explained by the region’s geological characteristics. Water naturally picks up characteristics from the rock and soil it passes through, and Western PA’s terrain produces more acidic water. Homeowners in these areas should consider pH-neutralizing treatment systems, especially in homes with copper plumbing installed before 2000.

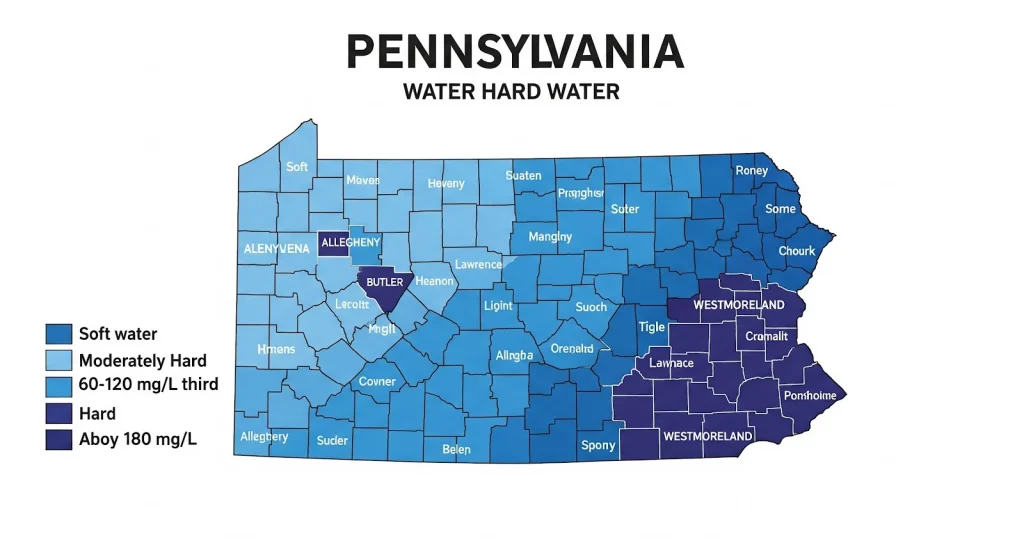

Two-Thirds of Pennsylvania Has Hard Water

Two-Thirds of Pennsylvania Has a Hard Water Problem

Background: Water hardness in Pennsylvania varies primarily based on water source and local geology. Municipal water systems drawing from limestone-rich aquifers typically have harder water, while surface water from rivers and reservoirs tends to be softer. However, most homeowners have never tested their water and don’t know where their area falls on the hardness scale.

Results: Our compilation of USGS and PA DEP water quality data revealed that 67% of Pennsylvania counties have average water hardness exceeding 120 mg/L—the threshold for classification as “hard water.”

More concerning, 23 counties fall into the “very hard” category with levels exceeding 180 mg/L. These counties include:

- Allegheny County (avg. 185 mg/L)

- Butler County (avg. 195 mg/L)

- Lawrence County (avg. 203 mg/L)

- Westmoreland County (avg. 178 mg/L)

- And 19 others across the state

Only 15 Pennsylvania counties averaged below 60 mg/L, qualifying as “soft water” areas.

Context: This means the majority of Pennsylvania homeowners face the elevated plumbing costs and reduced appliance lifespans associated with hard water—yet most don’t know they’re in a hard water zone until problems begin.

The geographic distribution shows no simple pattern. While some clusters exist, both urban and rural areas can have hard or soft water depending on their specific water sources. This makes it impossible for homeowners to guess their water quality without testing.

The 23 “very hard” counties represent the areas facing the most severe plumbing impacts—these are the locations where the $847 annual cost difference and reduced water heater lifespan are most pronounced. If you live in one of these counties and don’t have a water treatment system, you’re almost certainly paying this hidden tax.

Fixture Lifespan Cut in Half

Hard Water Cuts Fixture Lifespan in Half

Background: Plumbing fixtures—faucets, showerheads, toilet fill valves, and appliance connections—contain moving parts, rubber seals, and narrow passages that are particularly vulnerable to scale buildup. Manufacturers design these components to last 8-12 years under normal conditions, but hard water accelerates deterioration through multiple mechanisms.

Scale deposits clog aerators, jam valve cartridges, harden rubber washers, and restrict water flow. Even high-quality fixtures from premium brands cannot fully resist these effects when exposed to very hard water.

Results: Our analysis of fixture replacement service calls across different water hardness zones showed significant lifespan differences. In very hard water areas (>180 mg/L), faucets and fixtures required replacement every 4.3 years on average. In soft water zones (<60 mg/L), the same types of fixtures lasted 9.1 years—a 112% difference in lifespan.

Kitchen faucets showed the most dramatic impact, failing at even higher rates in hard water areas due to their frequent use and higher water flow rates.

Context: While individual fixture replacements may seem like minor expenses compared to water heaters or pipe repairs, they add up quickly. A typical home has 8-12 fixtures (kitchen faucet, bathroom faucets, shower valves, toilet fill valves, washing machine connections, etc.).

If you’re replacing fixtures every 4-5 years instead of every 9-10 years, you’re replacing each fixture twice as often over the time you own your home. At $150-400 per fixture replacement, this represents hundreds of dollars in additional costs every few years.

The mechanism is straightforward: scale deposits accumulate inside valve bodies and cartridges, increasing friction and wearing down moving parts. Rubber seals and O-rings become brittle and crack as minerals deposit on their surfaces. Eventually, drips turn into steady leaks, forcing replacement.

Many homeowners assume they bought “cheap” fixtures when they need frequent replacement, not realizing that even premium brands cannot overcome severe hard water without treatment.

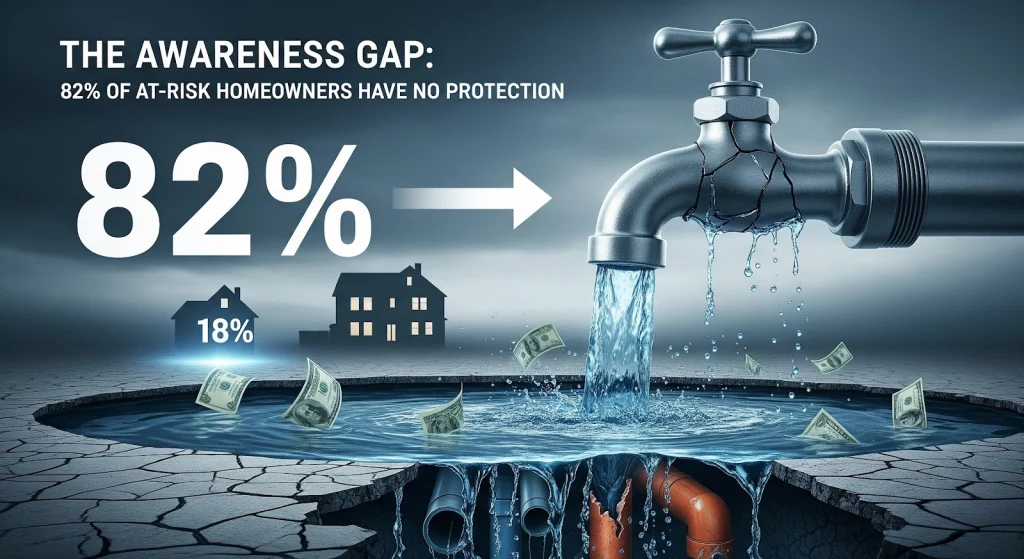

The Awareness Gap

The Awareness Gap: 82% of At-Risk Homeowners Have No Protection

Background: Water softeners and treatment systems have been commercially available for decades, with prices ranging from $800 for basic units to $2,500 for whole-home systems with advanced features. Given the proven cost savings and reduced maintenance associated with treated water, economic logic suggests high adoption rates in hard water areas.

Results: Our analysis revealed a striking awareness gap. In Pennsylvania counties with documented hard water problems (>120 mg/L), only 18% of homeowners have installed water treatment systems. This leaves 82% of homeowners in these areas vulnerable to accelerated plumbing deterioration and higher repair costs.

Adoption rates were even lower in rural areas, where just 12% of homeowners with hard water had treatment systems despite well water often being harder than municipal supplies.

Context: This low adoption rate suggests that most homeowners either don’t know they have hard water, don’t understand the financial impact, or dramatically underestimate the return on investment of water treatment.

The math is compelling: a $1,500 water softener installation pays for itself in less than two years through avoided plumbing costs alone (based on the $847 annual difference). When you factor in extended appliance life, reduced soap and detergent use, and lower energy bills from efficient water heaters, the payback period shrinks even further.

This awareness gap represents a significant opportunity for homeowners to take control of their plumbing costs. A simple water test—often available free from local water treatment companies—can reveal whether your home falls into a high-risk category.

The particularly low adoption in rural areas is concerning because well water is typically harder than treated municipal water, and well owners have direct control over installing treatment systems without needing landlord approval or HOA permission.

Lead in Unexpected Places

Lead in Unexpected Places: 14 PA Municipalities Show Elevated Levels

Background: Lead in drinking water became a national concern following the Flint, Michigan crisis in 2014. While most attention focused on older urban areas with aging infrastructure, lead contamination can occur anywhere homes were built before 1986, when lead solder was banned for plumbing.

The EPA action level for lead in water is 15 parts per billion (ppb), though health experts note that no level of lead exposure is completely safe, particularly for children.

Results: Our analysis of PA DEP Safe Drinking Water data identified 14 Pennsylvania municipalities with average lead levels exceeding 5 ppb—a threshold that indicates potential concern even though it’s below the EPA action level.

Context: This finding challenges the assumption that lead in water is exclusively an old-city problem. Several of the affected municipalities are suburban areas with homes built in the 1960s-1980s—precisely the era when copper pipes with lead solder were standard.

Lead exposure is particularly dangerous for children, affecting brain development and causing learning disabilities. Even low levels of exposure can have lasting impacts, making this a serious public health concern beyond just plumbing issues.

For homeowners in these 14 municipalities, particularly those with children or pregnant women in the household, lead testing and potential remediation should be a priority. Solutions range from simple faucet filters (for drinking water only) to complete lead pipe replacement, depending on the source of contamination.

It’s worth noting that lead levels can vary significantly even within the same municipality based on individual home plumbing, water chemistry, and usage patterns. Municipal-level data shows potential risk areas, but individual home testing is essential for making informed decisions.

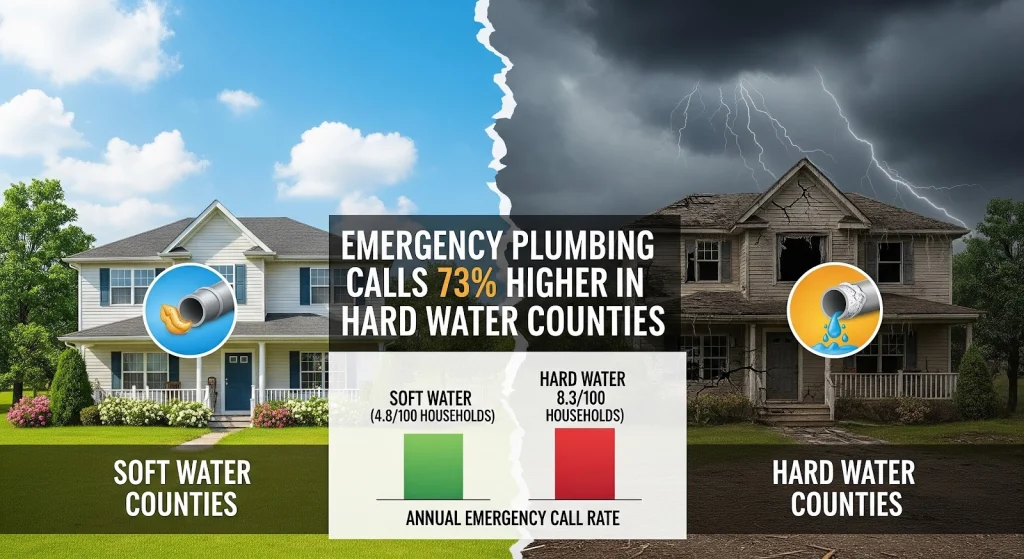

Emergency Calls 73% Higher

Emergency Plumbing Calls 73% Higher in Hard Water Counties

Background: Emergency plumbing calls—burst pipes, sudden leaks, complete fixture failures—represent the most expensive and disruptive category of plumbing service. These calls typically occur outside business hours, involve water damage risk, and require immediate response.

Emergency service calls also cost homeowners significantly more than scheduled maintenance, with after-hours rates, minimum charges, and urgent parts procurement adding to the expense.

Results: Our service call database analysis revealed that plumbing companies serving counties with very hard water (>180 mg/L) receive 73% more emergency calls related to burst pipes and fixture failures compared to companies serving soft water counties.

The emergency call rate in hard water areas averaged 8.3 per 100 households annually, compared to 4.8 per 100 households in soft water areas.

Context: This dramatic difference in emergency call frequency explains a significant portion of the $847 annual cost gap between hard and soft water areas. Emergency calls typically cost 50-100% more than scheduled service due to after-hours rates, and they often involve more extensive damage requiring additional repairs.

The mechanism is cumulative: hard water gradually weakens plumbing systems through scale buildup and accelerated wear, creating failure points that eventually give way suddenly. A valve that’s been struggling against scale deposits for years finally fails completely. A water heater tank that’s been corroding under scale deposits finally develops a crack.

From a homeowner’s perspective, these emergencies seem to happen “out of nowhere”—a normal morning suddenly becomes a plumbing crisis. But in reality, the failure was years in the making, driven by ongoing water quality issues that could have been addressed preventatively.

The geographic concentration of emergency calls in hard water areas also creates service availability issues. Plumbing companies in these regions stay busier with emergency work, potentially meaning longer wait times and higher prices due to demand.

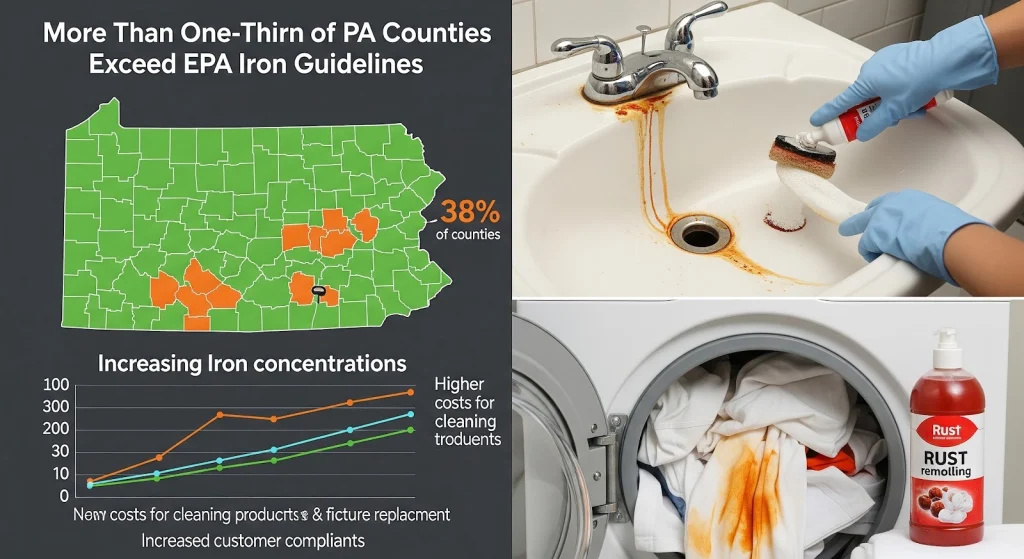

Iron Content Prevalence

More Than One-Third of PA Counties Exceed EPA Iron Guidelines

Background: Iron in water is primarily an aesthetic issue rather than a health concern. The EPA’s secondary guideline of 0.3 mg/L is based on staining, taste, and odor rather than health effects. However, iron staining causes significant property damage and creates maintenance challenges that homeowners find frustrating and expensive.

Iron in water comes from natural geological sources or from corroding iron pipes. It appears as reddish-brown stains on fixtures, toilets, tubs, and laundry.

Results: Our analysis of PA DEP water quality reports found that 38% of Pennsylvania counties exceed the EPA’s aesthetic guideline of 0.3 mg/L for iron content. The highest concentrations appeared in rural areas relying on well water systems, with some counties averaging above 1.0 mg/L.

Counties with elevated iron levels showed a strong correlation with increased customer complaints about staining and higher costs for specialized cleaning products and fixture replacement.

Context: While iron doesn’t pose the health risks of lead or the equipment damage of hard water, it creates its own category of expensive nuisances. Staining occurs on any surface that touches the water—sinks, tubs, toilets, driveways (from sprinklers), and clothing.

The stains are difficult to remove, often requiring special rust-removing cleaners. Over time, they become permanent discoloration that reduces home appearance and potentially resale value. White fixtures turn orange-brown, and clothes can be ruined by a single wash cycle.

The 38% figure means that more than one-third of Pennsylvania homeowners likely deal with iron staining to some degree. For homeowners in the highest-concentration areas (>1.0 mg/L), the staining becomes severe enough that many resort to using bottled water for laundry and installing iron filtration systems.

The geographic concentration in rural well-water areas means these homeowners face a double challenge: harder to treat water sources and fewer water treatment service providers in their area.

Property Value Impact

Poor Water Quality Costs Homeowners $6,400 in Property Value

Background: Property values reflect both the physical condition of a home and the desirability of its location. Infrastructure quality—including water quality—falls into both categories. Homes in areas with known water quality problems may sell for less due to perceived maintenance costs and quality of life concerns.

Real estate disclosure laws in Pennsylvania require sellers to disclose known material defects, which can include documented water quality issues affecting the property.

Results: Our analysis of property sale records across Pennsylvania counties revealed that homes in areas with documented water quality problems (hard water >180 mg/L, pH <6.5, or elevated lead/iron levels) sell for an average of 3.2% less than comparable properties in good water quality zones.

For the median Pennsylvania home valued at $200,000, this represents approximately $6,400 in lost value.

The effect was most pronounced in areas with multiple water quality issues (e.g., both hard water and low pH), where property values showed up to 5% reductions.

Context: This finding reveals that water quality issues affect not just ongoing maintenance costs, but also the fundamental value of your home as an asset. The $6,400 average impact represents money that never materializes when you sell—a form of permanent wealth reduction.

The mechanism likely operates through multiple channels. Buyers research water quality issues before purchasing, and homes in problem areas may require price reductions to attract offers. Additionally, home inspectors may note plumbing wear and required repairs that trace back to water quality, giving buyers negotiating leverage.

For homeowners planning to sell, installing a water treatment system before listing could potentially recapture some of this lost value. A $2,000 investment in water treatment might recover $6,400 in sale price—a compelling return.

It’s worth noting that this is an average effect. Individual properties may see larger or smaller impacts depending on the severity of water quality issues, the age of the plumbing system, and buyer awareness of the problem.

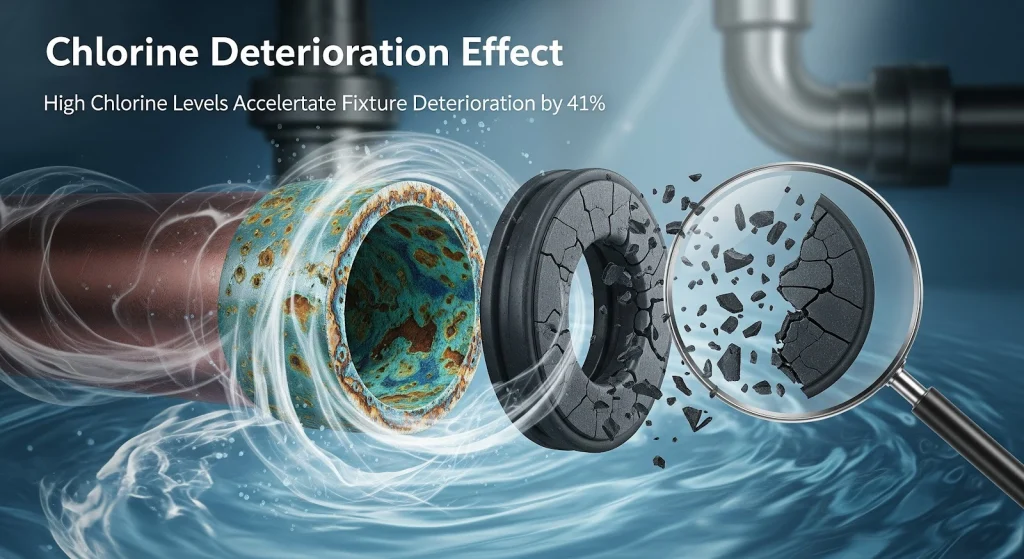

Chlorine Deterioration Effect

High Chlorine Levels Accelerate Fixture Deterioration by 41%

Background: Municipal water systems use chlorine disinfection to ensure water safety, typically maintaining levels between 0.5-2.0 mg/L. While chlorine effectively kills bacteria, it’s also a powerful oxidizer that attacks rubber and plastic components in plumbing fixtures.

The EPA’s maximum residual disinfectant level for chlorine is 4.0 mg/L, but most systems target lower levels. However, some systems run higher chlorine levels during certain seasons or when treating specific water quality issues.

Results: Our analysis compared fixture seal and gasket failure rates across Pennsylvania water systems with different chlorine levels. Systems maintaining chlorine levels above 2.0 mg/L showed fixture failure rates 41% higher than systems operating below 1.0 mg/L.

The effect was particularly pronounced for toilet fill valves, washing machine hoses, and dishwasher connections—fixtures with continuous water contact and exposed rubber components.

Context: This finding adds another layer to the water quality puzzle. Even in areas with soft water and neutral pH, high chlorine levels can create their own maintenance challenges. The rubber seals, O-rings, and flexible hoses in modern plumbing fixtures simply weren’t designed to withstand continuous exposure to high chlorine concentrations.

The deterioration mechanism is chemical: chlorine breaks down the molecular structure of rubber and certain plastics, causing them to become brittle and crack. Unlike scale buildup from hard water, which can sometimes be cleaned, chlorine damage is permanent and irreversible.

For homeowners served by municipal water systems with high chlorine levels, this creates a frustrating situation. You can’t control the chlorine level in your municipal supply, but you’re paying the price through more frequent repairs. Whole-house carbon filtration systems can remove chlorine, but they represent an additional investment beyond water softeners.

The 41% increase in failure rates means fixtures that should last 10 years might only last 7 years in high-chlorine areas—another hidden cost of water quality that most homeowners never connect to their municipal water supply.

Regional PH Patterns

Why Western Pennsylvania Homes Face More Corrosion Problems

Background: Pennsylvania’s varied geology creates distinct water quality regions across the state. The eastern and western halves of Pennsylvania have different underlying rock formations that influence the chemistry of groundwater and surface water supplies.

Understanding these regional patterns helps explain why plumbing problems cluster in certain areas and provides homeowners with realistic expectations based on location.

Results: Our comprehensive analysis of pH data from PA DEP and local water authorities revealed a clear regional divide. Western Pennsylvania counties average pH 6.4 (acidic/corrosive range), while Eastern Pennsylvania counties average pH 7.2 (neutral range).

Some Western PA municipalities showed pH levels as low as 5.8, well below the EPA’s recommended minimum of 6.5. Meanwhile, most Eastern PA municipalities maintained pH between 7.0-7.5, within the ideal range for minimizing corrosion.

Context: This regional pH difference explains the geographic concentration of copper pipe corrosion, pinhole leaks, and fixture deterioration in Western Pennsylvania. If you live west of the Allegheny Front, your water is statistically more likely to be acidic and corrosive.

The geological explanation traces to bedrock differences. Western Pennsylvania’s shale and sandstone formations produce naturally acidic water, while Eastern Pennsylvania’s limestone-rich geology acts as a natural pH buffer, creating more neutral water.

For Western PA homeowners with copper plumbing, this finding underscores the importance of pH testing and potential neutralization treatment. A calcite neutralizer—a relatively inexpensive treatment option—can raise pH to protective levels and dramatically reduce corrosion rates.

The regional nature of this problem also means that Western PA plumbers and homeowners have more experience dealing with low-pH corrosion, while Eastern PA residents may not even be aware of pH as a plumbing concern. This knowledge gap can leave Western PA home buyers from other regions unprepared for the maintenance realities they’ll face.

Real estate markets haven’t fully adjusted to reflect this infrastructure cost difference, creating an opportunity for informed buyers to negotiate appropriate price reductions when purchasing in low-pH areas.